|

|

|

|

|

|

|

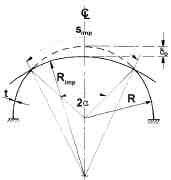

| Hemispherical shell with a "flat" spot. The "imperfect" shell is to be externally pressurized |

|

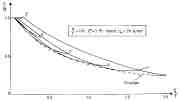

| How the lower bound of the collapse pressure, Pc, is determined as a function of the flattening amplitude, delta0 |

|

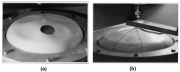

| Molded torispherical shells fabricated of plastic ABS material. The shells have off-axis "flat" spots with geometry of the type shown two slides ago. |

|

| This slide shows the buckled specimens that in the previous slide are shown before testing under external pressure |

|

| Comparison between test and theory for the torispherical shells with "flat" regions spanning increasing alpha (increasing delta0) |

|

|

|

|

|

|

|

|

|

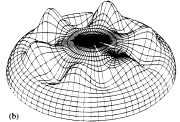

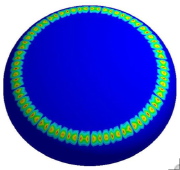

| Finite element model of externally pressurized torispherical shell with small "flat" spot |

|

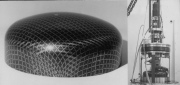

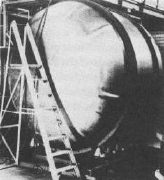

| Buckled plastic externally pressurized, meridionally stiffened torispherical shell |

|

| 350 mm diameter laminated composite torispherical shell fabricated by draping. The shell is to be tested under uniform external pressure |

|

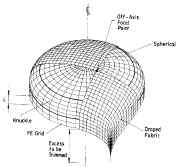

| How the draping is done and modeled for the fabricated specimen shown in the previous slide |

|

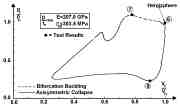

| Failure diagram of perfect externally pressurized torispherical shells |

|

|

|

|

|

|

|

|

|

| Linear buckling mode of an internally pressurized torispherical pressure vessel head |

|

| Internally pressurized torispherical vessel |

|

| Typical post-buckling pattern of an internally pressurized torispherical or ellipsoidal steel or aluminaum pressure vessel head |

|

| Axisymmetric elastic-plastic deformation of an internally pressurized ellipsoidal shell predicted by BOSOR5 |

|

| Post-buckling of an internally pressurized torispherical pressure vessel head from ANSYS finite element model |

|

|