|

|

|

|

|

|

|

| Buckling of paper: The colored (outer) portion was sprayed with ink, causing expansion of the moist paper, which was constrained by the untreated and undeformed circular white region. |

|

| Morphing shapes from bilayers |

|

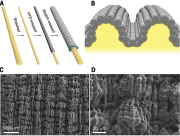

| Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles |

|

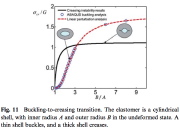

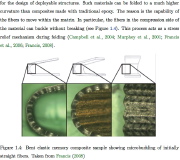

| Thick shell buckling and internal void creasing under external osmotic pressure |

|

| Examples of curvature-induced buckling of shells |

|

|

|

|

|

|

|

|

|

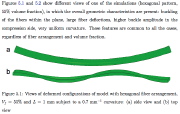

| Composite fiber microbuckling on the compressive side of a laminate bent (folded) 180 degrees (Image No. 1 of 9) |

|

| In-plane buckling of fibers in a fiber-silicone laminate that has been bent (folded) almost 180 degrees (Image No. 2 of 9) |

|

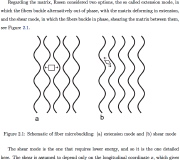

| Fiber microbuckling with two possible deformation modes of the soft silicone matrix (Image No. 3 of 9) |

|

| Unit cell model for fibers arranged in a hexagonal pattern (Image No. 4 of 9) |

|

| Imposed uniform bending (folding: imposed radius of curvature, R) (Image No. 5 of 9) |

|

|

|

|

|

|

|

|

|

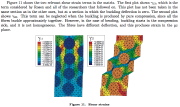

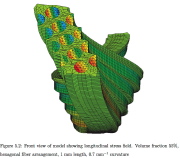

| Unit cell (a) bending (folding) and (b) buckling in the plane of the composite laminate. (Image No. 6 of 9) |

|

| Unit cell finite element model showing several axial (x) half-waves of the buckling pattern and showing deformations of the unit cell cross sections at 4 stations (Image No. 7 of 9) |

|

| Unit cell shearing strains in the bent (folded) cross sections at two axial (x) locations where the maximum shear strains occur (Image No. 8 of 9) |

|

| Unit cell finite element model of 1.5 full axial (x) waves of the fiber/matrix buckling pattern in the plane of the laminated composite (Image No. 9 of 9) |

|

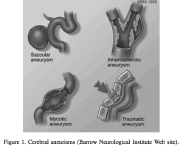

| Aneuryisms arise from internal pressure in a thick-walled cylindrical "shell" (blood vessel) |

|

|