|

|

|

|

|

|

|

| Shell plate buckling eyed in box ship break-up |

|

| DLR’s buckling test facility: left: axial compression configuration; right: compression-shear- configuration |

|

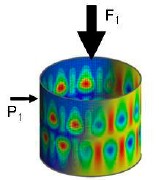

| The small load, P1, creates an imperfection that reduces the carrying capacity of the axially compressed cylindrical shell |

|

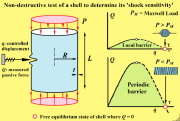

| Non-destructive test suggested by J.M.T Thompson for buckling of an axially compressed cylindrical shell |

|

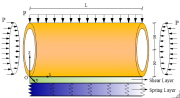

| Hydrostatically compressed cylindrical shell on a Pasternak foundation |

|

|

|

|

|

|

|

|

|

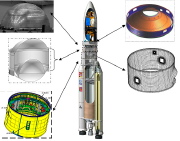

| Some parts of a rocket that can buckle (DESICOS workshop: new robust DESign guideline for Imperfection sensitive COmposite launcher Structures) |

|

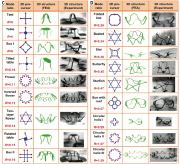

| Assembly of micro/nanomaterials into complex, three-dimensional architectures by compressive buckling |

|

| Buckling in 3D Structures investigated by the Bertoldi Group at Harvard University |

|

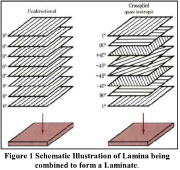

| Schematic illustration of lamina being combined to form a laminate |

|

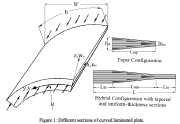

| Buckling of axially compressed, curved composite shell containing tapered sections |

|

|

|

|

|

|

|

|

|

| Detail of a tapered section including resin-rich layers |

|

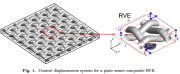

| Model used for the properties of a lamina in connection with multi-scale computational homogenization frameworks for the non-linear behavior of heterogeneous thin shells |

|

| Finite element discretization of the lamina shown in the previous slide |

|

| Building up a laminate consisting of layers modeled as displayed in the previous 2 slides |

|

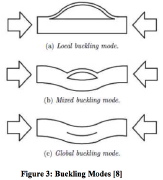

| Three modes of buckling of an axially compressed flat plate with a local delamination |

|

|