|

|

|

|

|

|

|

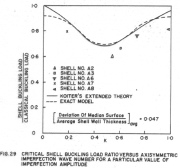

| Test v. theory for five specimens with the same axial wavelength of manufactured axisymmetric sinusoidal imperfections with various amplitudes |

|

| Buckling of axisymmetrically imperfect cylindrical shells with normalized imperfection amplitude = 0.047 and various imperfection axial wavelengths |

|

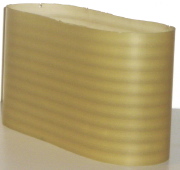

| Spun cast cylindrical shell with intentionally manufactured non-axisymmetric imperfection pattern |

|

| Buckling of a nonsymmetrically imperfect axially compressed photoelastic cylindrical shell from high-speed photography of 45 deg. isoclinics |

|

| Near-perfect (middle), axisymmetrically imperfect (left) and non-axisymmetrically imperfect (right) cylindrical shells |

|

|

|

|

|

|

|

|

|

| Oval photoelastic cylindrical shell with intentionally manufactured "axisymmetric" initial imperfection |

|

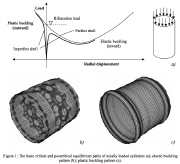

| Elastic and plastic buckling of an axially compressed cylindrical shell |

|

| High-speed film of dynamic buckling of a thin cylindrical shell under axial impact |

|

| Buckling of a cylindrical shell under torsion |

|

| Buckled cylindrical shell installed in Yamaki's test rig |

|

|

|

|

|

|

|

|

|

| Buckled short cylindrical shell under torsion |

|

| Buckled longer cylindrical shell under torsion |

|

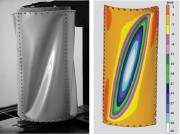

| Deep post-buckling of skin of cylindrical shell with widely spaced stiffeners; loading=torque: from test (left); from finite element model (right) |

|

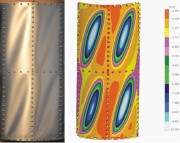

| Post-buckling of skin of cylindrical shell with widely spaced rings and stringers; loading=torque: from test (left); from finite element model (right) |

|

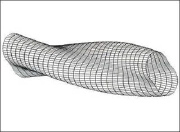

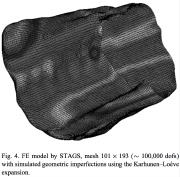

| A typical imperfection shape (greatly exaggerated) in a STAGS finite element model of a thin cylindrical shell |

|

|